Dunwoody students and faculty are celebrating the installation of the College’s newest piece of equipment- a Kongsberg V20 CAD (Computer-Aided Design) Table. Kongsberg, a division of Esko, Inc. (a valued partner to the Design & Graphics Technology department) manufactures its tables in the Czech Republic and sells them worldwide.

The new table and software allows users to design and produce cartons, containers, retail displays, signage and die cut art made from a wide array of materials including paper, plastic and corrugated cardboard. The upgraded table cuts 1,150 inches per minute- nearly 10 times faster than the College’s previous CAD table.

While students of multiple Dunwoody design programs will use and benefit from this new piece of equipment, perhaps those most excited are students of the Design & Graphics Technology department, particularly first years enrolled in the “Intro to Packaging Design” course.

The Packaging Design course, a class required for both Pre-Media and Graphic Design programs, centers around a semester-long project requiring students to work one-on-one with real customers on the design and production of a custom package using the CAD table’s 2015 technology.

The project begins once the student identifies a real customer (e.g., a Dunwoody staff member, instructor or a local business owner) who is in need of a container or package for a certain product.

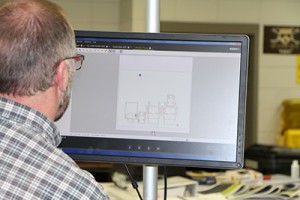

Keeping in mind the ultimate purpose or goal of the container, the student begins to design a template for the package using Esko’s ArtiosCAD design software. The resulting file is transferred without further conversion to the CAD table’s computer, which runs Esko’s iCut Production Suite software.

Keeping in mind the ultimate purpose or goal of the container, the student begins to design a template for the package using Esko’s ArtiosCAD design software. The resulting file is transferred without further conversion to the CAD table’s computer, which runs Esko’s iCut Production Suite software.

The package’s template will ultimately consist of a large collection of lines (pictured above) that tells the table where the material must be cut, perforated or creased for folding.

Once the template has been finalized and the designer has chosen an appropriate type of material to cut, the computer will send a message to the table’s tool head (pictured right) to begin cutting.

Once the template has been finalized and the designer has chosen an appropriate type of material to cut, the computer will send a message to the table’s tool head (pictured right) to begin cutting.

The designer then “pops out” the design (pictured below), assembles the container and issues it to the customer. Should the prototype be something the customer is genuinely interested in using or distributing, the student may share the design template with a larger production house for mass production. Any single design can be stepped and repeated or ganged with other design templates before cutting to maximize productivity and minimize waste. All scrap corrugated and paper is collected for recycling (pictured below), quite often returning in the form of new corrugated sheets.

At the end of the semester students are graded on their knowledge of the CAD table as well as their ability to successfully work with clients, and design and produce a purposeful, real-life product. The project is a great opportunity for students to network, build their resumes and portfolios and experience design and production in its entirety.

“There is a lot of excitement throughout the department right now,” says Pete Rivard, Principal Instructor of Pre-Media Technologies, when discussing the recent installation. “Students are having a hard time paying attention in Photoshop class because they are too busy refining their package designs! Although we obviously want them to pay attention to their other courses, it is neat to see them so excited about their projects. Package design is a complex process. Nobody gets it right the first time, even out in industry. So to have this table in our lab gives every student in the program a second, third or seventeenth chance to adjust their designs to meet the demands of the material. The finished result should be the equal to any carton on any store shelf anywhere.”

The 2015 table is also generating buzz throughout the community as Dunwoody is currently the only College in the state of Minnesota that has this table for the use of packaging and retail display design. Dunwoody also enjoys the support of local corrugated manufacturer and box design business Liberty Carton, who happily provides the graphics program with all the corrugated material it needs.

“The table also helps with the ‘hands-on’ piece of Dunwoody’s curriculum,” says Rivard. “Because of this table, our students will not only learn the process of packaging design, but will really get to experience it first hand. The act of manually folding and assembling and evaluating a physical object that you yourself designed and cut is a powerful experience, and causes students to want to do better.”

Rivard plans to continue the momentum this table has brought by providing CAD table demonstrations for design students and faculty from various Minnesota colleges, as well as professionals in the design and packaging industry, at the upcoming AIGA PIVOT event on April 22.

Dunwoody’s Design & Graphics Technology department offers AAS degrees in both Graphic Design and Pre-Media Technologies.